Great work Timmy  This is a great thread, I was very excited to read all of it!

This is a great thread, I was very excited to read all of it!

Dan

This is a great thread, I was very excited to read all of it!

This is a great thread, I was very excited to read all of it!Dan

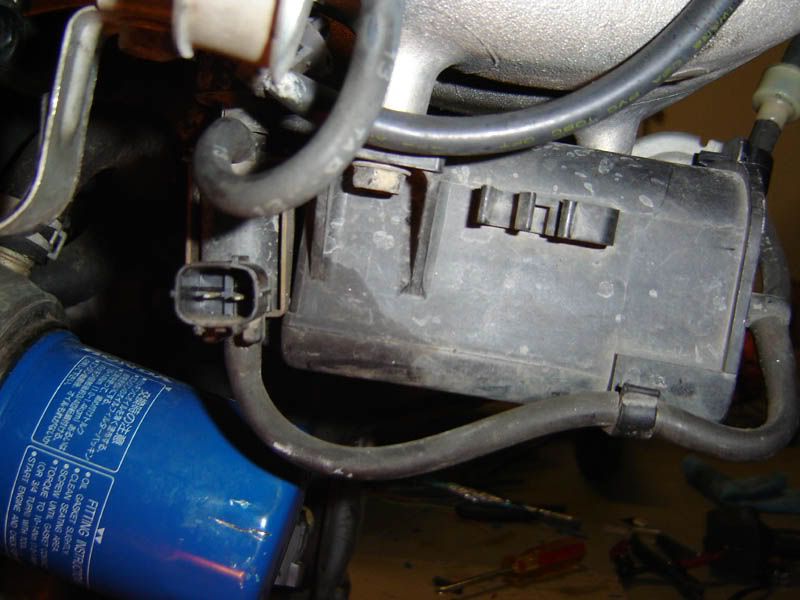

. but of course i want the car in its best shape before testing. the check engine light owns me right now!

. but of course i want the car in its best shape before testing. the check engine light owns me right now! .

.

. a handful of people saw it though including ron. i hope for you to see it soon too

. a handful of people saw it though including ron. i hope for you to see it soon too  .

.

.

.

!

! .

.

.

.

.

.

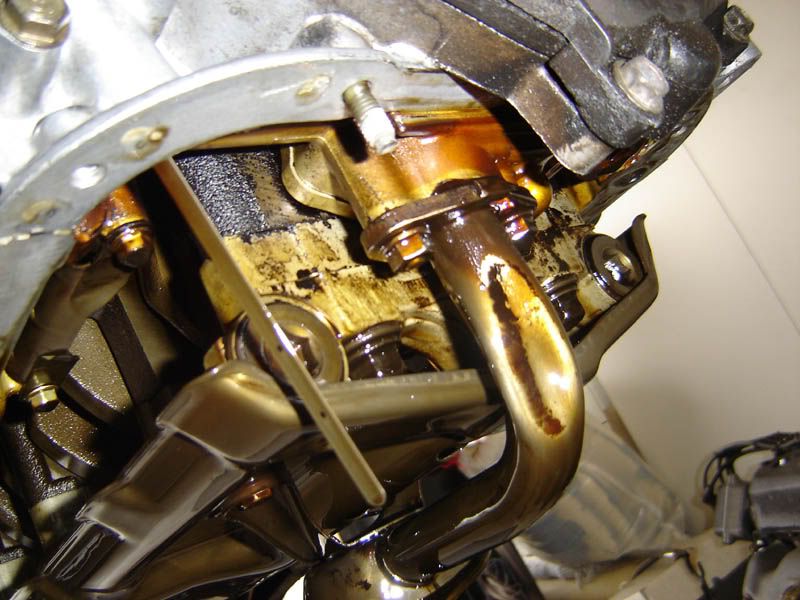

! what the heck happened? this could be why i got the motor for a cheaper price than usual.

! what the heck happened? this could be why i got the motor for a cheaper price than usual.

Comment