You are making fast winter project progress!!! I am envious.

I also hate that the engine stand interferes with the hoist. It is a conundrum.

I also hate that the engine stand interferes with the hoist. It is a conundrum.

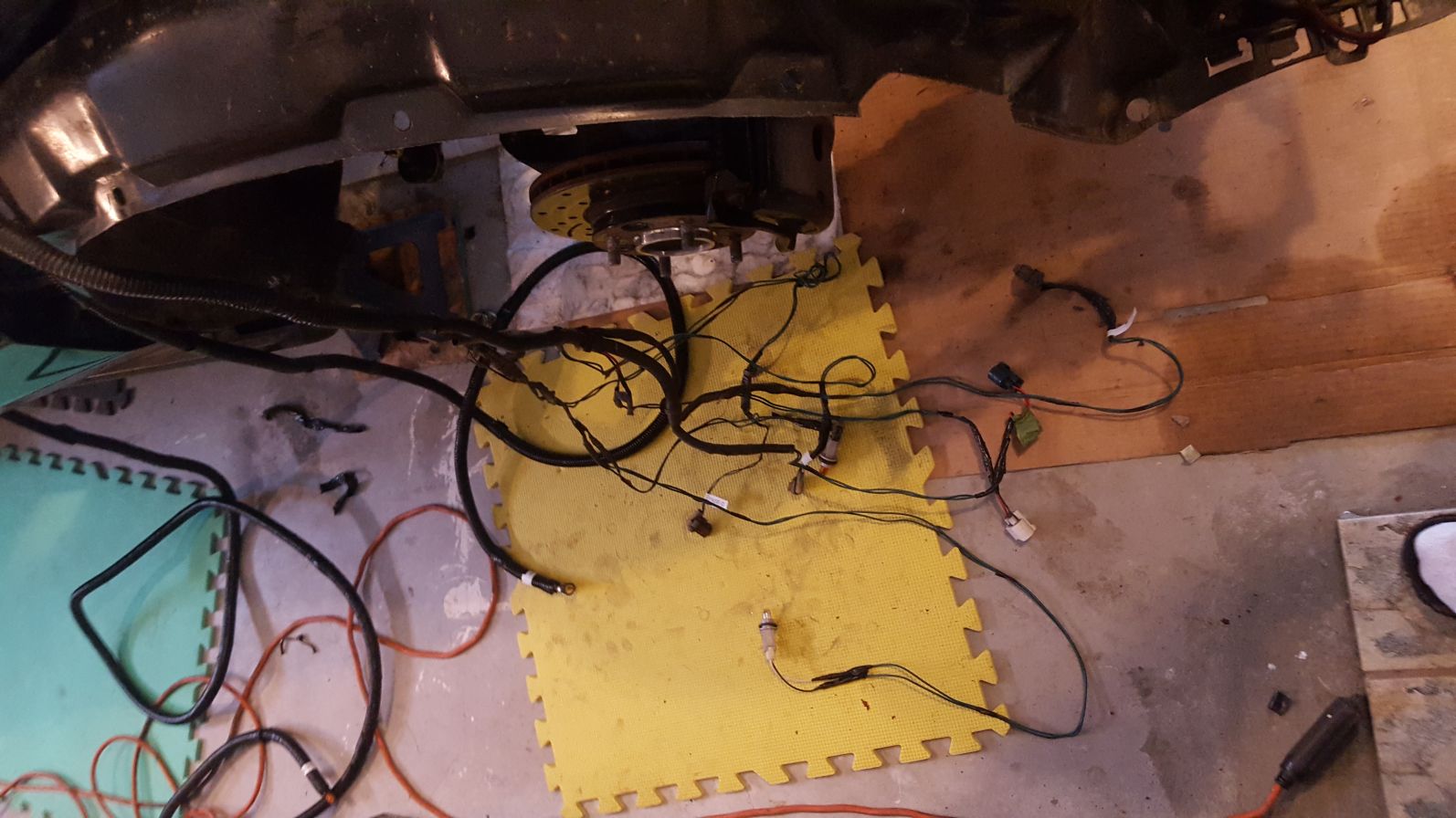

Here's a vid sped up x1000 of me trying to put the engine on the stand...grrrrrrrrr.

Here's a vid sped up x1000 of me trying to put the engine on the stand...grrrrrrrrr.

Here's a vid sped up x1000 of me trying to put the engine on the stand...grrrrrrrrr.

Here's a vid sped up x1000 of me trying to put the engine on the stand...grrrrrrrrr.

Comment