- All wires protected with wire loom

- Meth fuel line and controller boost line run under the car (in the brake line / fuel line tray)

- Electrical lines run up drivers side

- Pump secured to trunk floor

- Tank & controller installed

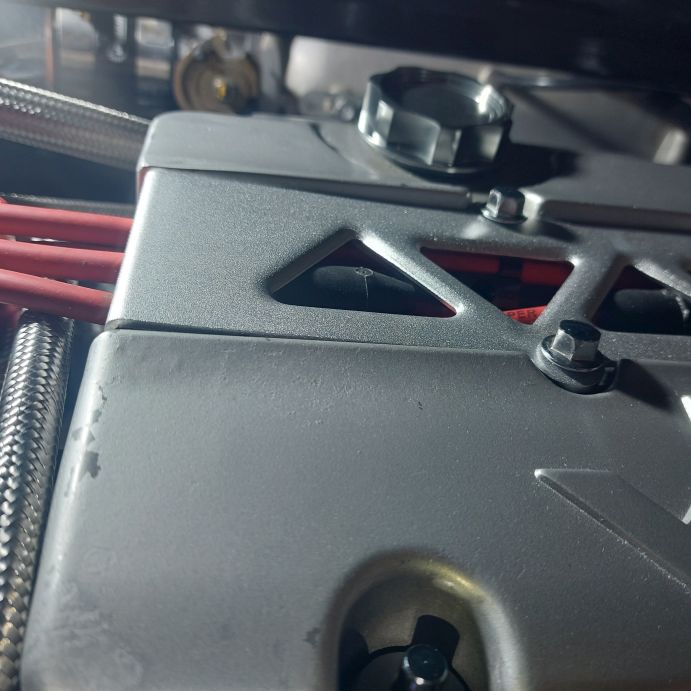

still run this battery setup. two reds are for each amp.

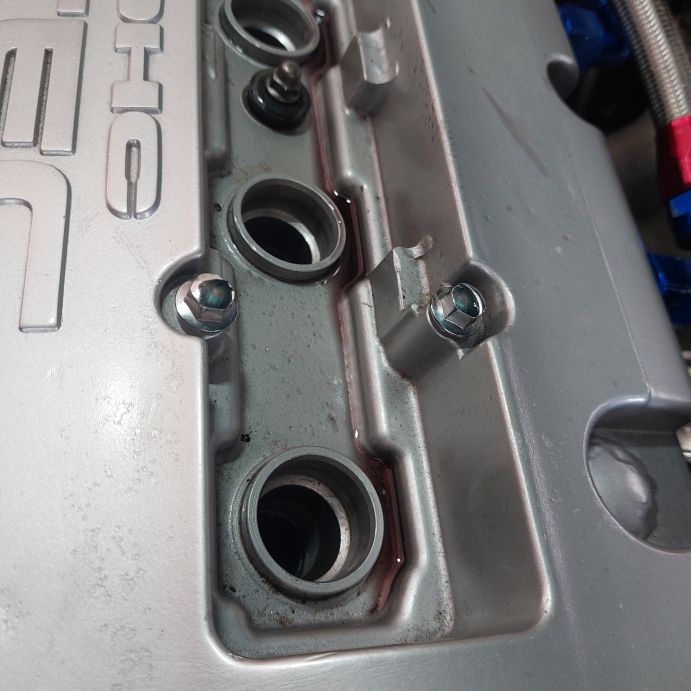

The belt still had tension, just the lower cog could spin freely. No damage, compression tested 170+ across the board. Put it all back together (was not easy) and it started up perfect!

The belt still had tension, just the lower cog could spin freely. No damage, compression tested 170+ across the board. Put it all back together (was not easy) and it started up perfect!

. OK. ordering new hardware.

. OK. ordering new hardware.

Leave a comment: