Alllllllll right  I guess I can start this back up. I was taking a break for numerous reasons. Good to not throw too much at the car as well. I already have to keep in mind of the negative battery cable and other electrical items.

I guess I can start this back up. I was taking a break for numerous reasons. Good to not throw too much at the car as well. I already have to keep in mind of the negative battery cable and other electrical items.

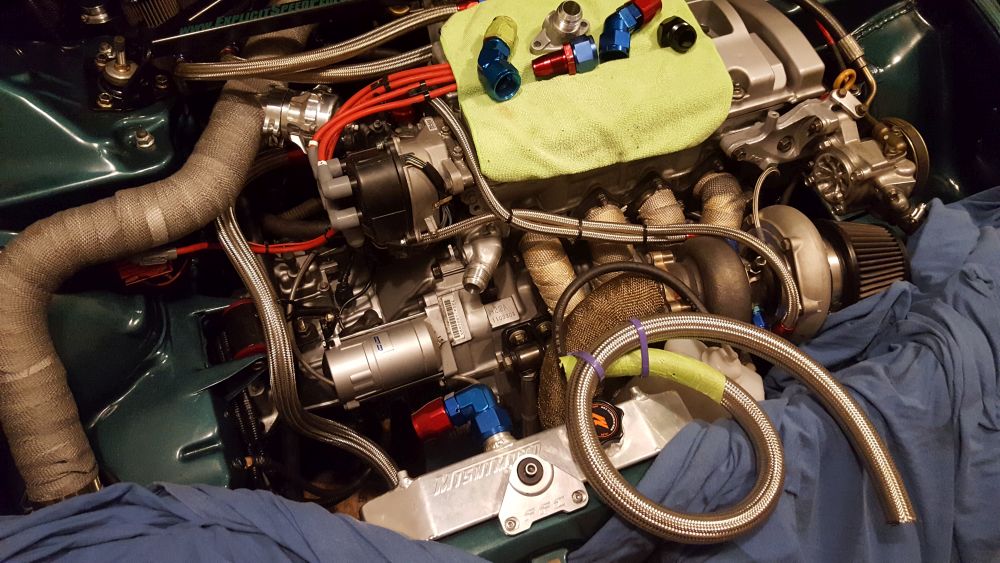

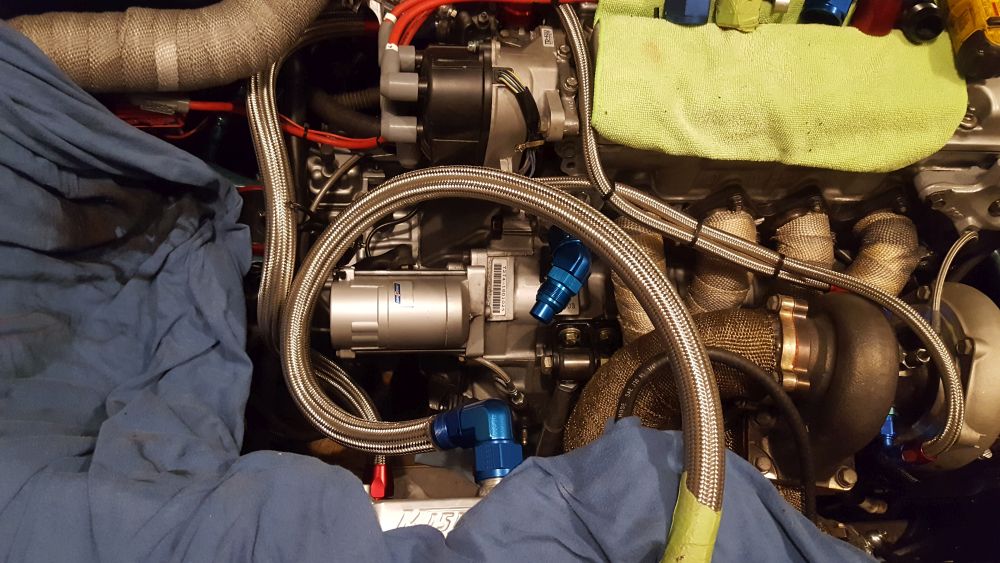

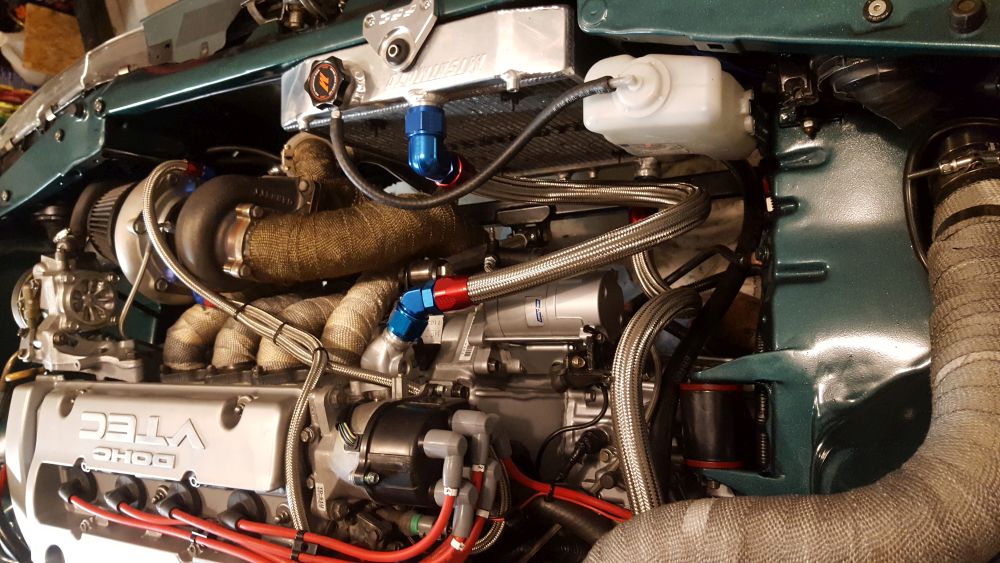

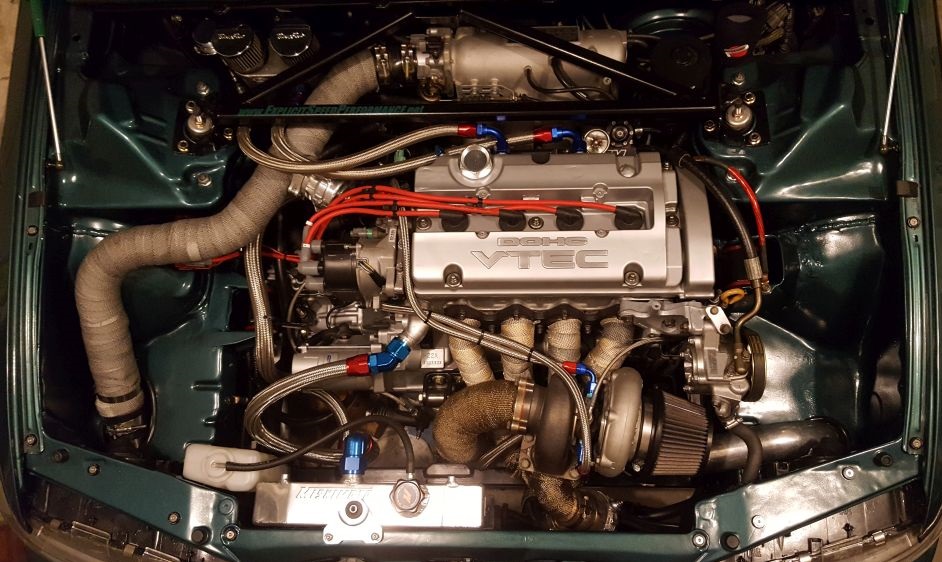

But....... this. Ohhh this. I've spent hundreds on labor and parts. This is simply not possible! Well, not with out moving the radiator or some major fab work. I've got all the ends in the world but.... you'll see....

- The original issue was finding a -16AN hose that would work between the rad and engine block.

- I thought two 45deg ends would work but the offset is too much for the stiff braided line

If I attempted to use two 45deg ends + an extender. No go. The angle difference + offset is too much for the braided line to bend.

We could do this....... naaaa. This is as much of a bend you'll get out of the hose. So a 90deg. on each end will not work either.

It's almost like I need a 22.5deg -16AN fitting. But they don't exist.

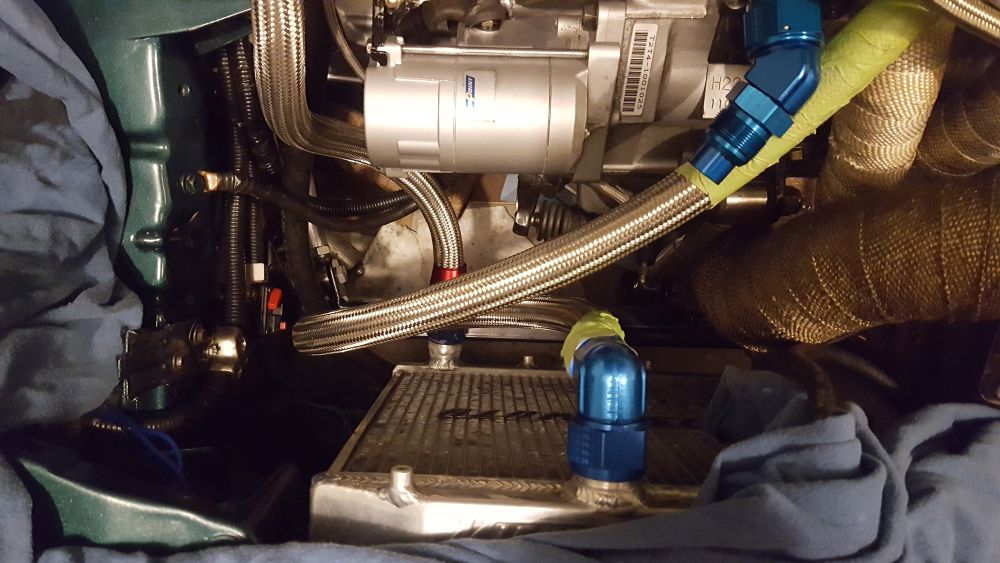

The problem in the end is that the distance is so short that the hose becomes very rigid. Not only does it allow zero movement (not that my engine moves anyways), but it will transfer the load/vibrations from the engine to the rad connection and the upper rad body portion. There's no room to make a U-shape hose going down behind the rad with two 90deg fittings.

The real answer here is to have the rad moved, requires re-welding rad supports and re-creating air block off areas.

or

Have the rad neck piece moved on the rad.

For now........ I'm going to cheat. And already ordered what I need.

I guess I can start this back up. I was taking a break for numerous reasons. Good to not throw too much at the car as well. I already have to keep in mind of the negative battery cable and other electrical items.

I guess I can start this back up. I was taking a break for numerous reasons. Good to not throw too much at the car as well. I already have to keep in mind of the negative battery cable and other electrical items. But....... this. Ohhh this. I've spent hundreds on labor and parts. This is simply not possible! Well, not with out moving the radiator or some major fab work. I've got all the ends in the world but.... you'll see....

- The original issue was finding a -16AN hose that would work between the rad and engine block.

- I thought two 45deg ends would work but the offset is too much for the stiff braided line

If I attempted to use two 45deg ends + an extender. No go. The angle difference + offset is too much for the braided line to bend.

We could do this....... naaaa. This is as much of a bend you'll get out of the hose. So a 90deg. on each end will not work either.

It's almost like I need a 22.5deg -16AN fitting. But they don't exist.

The problem in the end is that the distance is so short that the hose becomes very rigid. Not only does it allow zero movement (not that my engine moves anyways), but it will transfer the load/vibrations from the engine to the rad connection and the upper rad body portion. There's no room to make a U-shape hose going down behind the rad with two 90deg fittings.

The real answer here is to have the rad moved, requires re-welding rad supports and re-creating air block off areas.

or

Have the rad neck piece moved on the rad.

For now........ I'm going to cheat. And already ordered what I need.

Comment