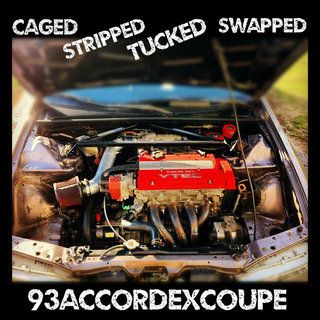

so im in the process of doing an h23 upper plenum swap on my car. (f22a6). i am using the IAB plate from the h23 as a spacer to go on my intake manifold. so i took the secondary valves out of it and i have a crap load of holes running through the plate. so my question is, do i JB weld every single hole? or just the ones on the end to make sure i have no vacuum leaks. i know the ones on the end definitely have to be sealed. but do the small ones inside really need to be. i mean they run right into the next runner and no air will be escaping, except to the runner right next to it.

Announcement

Collapse

No announcement yet.

h23 upper plenum help

Collapse

X

-

k its all put back together and in the car. i ended up not filling them because i didnt see these replies until it was done. im going to get to it eventually when its not -50 out. it seems to be running perfect and driving great. the gains are awesome in the top end. the only thing its doing which is kinda weird is at cruising speed around town (40-50) it sits at just under 2k rpms and when i hit the gas again it gives a little bog but then its fine. if im under WOT there are no bogs or sputters at all. anyone got any ideas?

Comment

Comment