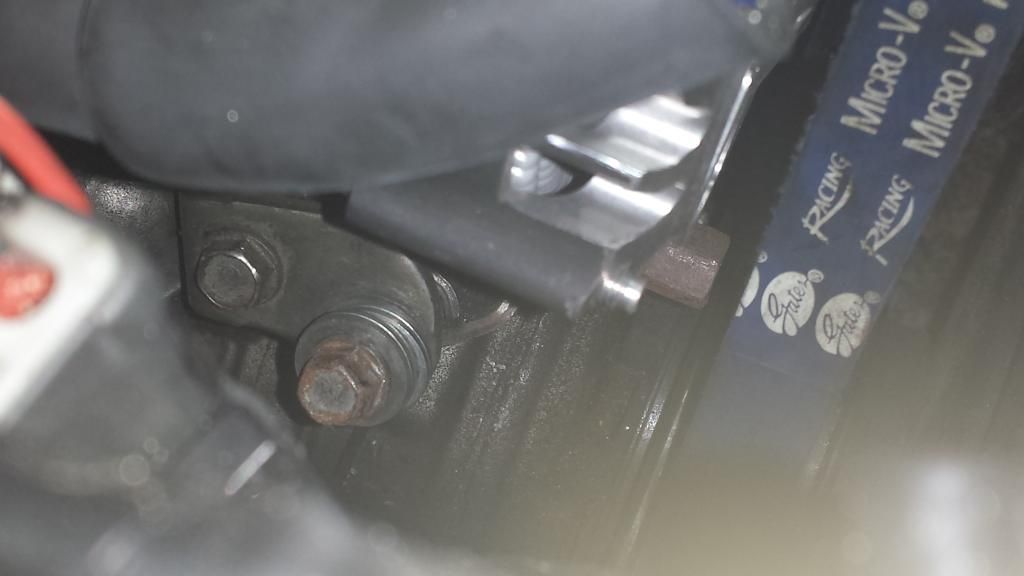

After testing my alternator at Autozone, I went to reinstall it. During installation, I mistakenly tightened the nut for the bolt in the tensioner track before I started tightening the tensioner bolt. I noticed how hard it was to tighten that 10mm bolt. Then my hand slipped and I noticed that the little bracket connecting the two bolts was really bent from my blunder. It is bent to the point that some metal shards from the tensioner bolt are visible from my tightening, so I am stripping the thread somewhat.

As a quick remedy, I loosened a little of the pressure on that little bracket by loosening the tensioner bolt, and really tightened that nut for the bolt on the tensioner track with the belt pretty taught. I have not started the car yet for fear that the belt might go slack if the bolt in the track slips slightly over time.

The question I have for you guys is this: do I need to get a new little bracket and tensioner bolt right away, or am I fine leaving things the way they are until I actually need a new alternator?

I can post pictures if they are needed.

Thank you for your help.

As a quick remedy, I loosened a little of the pressure on that little bracket by loosening the tensioner bolt, and really tightened that nut for the bolt on the tensioner track with the belt pretty taught. I have not started the car yet for fear that the belt might go slack if the bolt in the track slips slightly over time.

The question I have for you guys is this: do I need to get a new little bracket and tensioner bolt right away, or am I fine leaving things the way they are until I actually need a new alternator?

I can post pictures if they are needed.

Thank you for your help.

.

. .

.

Comment