Originally posted by d112crzy

yea i was doing the mearsurements on paper but it didnt come out right... like negative numbers....

i used: BT= (BH - JD - BC)/2

based off the equation:

BC = BH - JD -(2xBT)

BC = bearing clearance

BH = Bore housing diameter

JD = journal diameter

BT = Bearing thickness

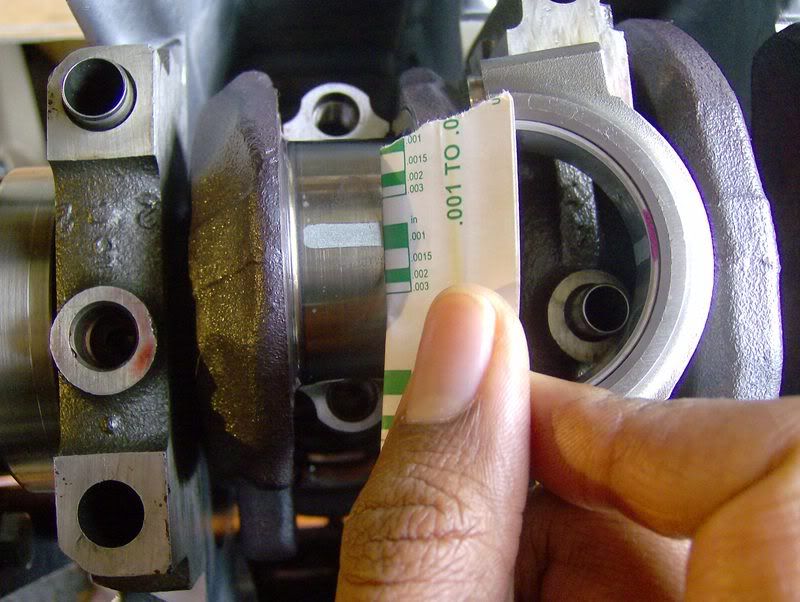

i used a digital dial caliper that can only go one-thousands (0.001) of an inch on all measurements...but do i need to soley need to use a micrometer...

Comment